Soil Stabilization System Equipment

Yichen® Soil Stabilization System Equipment Product IntroductionWith nearly 20 years of experience in the development of excavator attachments and the Soil Stabilization System Equipment, Yichen is a professional soil stabilization system equipment supplier. In 2015, YICHEN independently design......

Send Inquiry

Product Description

Yichen® Soil Stabilization System Equipment Product Introduction

With nearly 20 years of experience in the development of excavator attachments and the Soil Stabilization System Equipment, Yichen is a professional soil stabilization system equipment supplier. In 2015, YICHEN independently designed and developed the world's leading soil stabilization technology, and is the first company in the world to use a more environmentally friendly solid to liquid stabilizer construction technology. Based on the premise of environmental protection and energy saving, the technology realizes the in situ solidification of soft foundation, sludge and soft soil of roadbed, swamp, landfill, beach coating, river course and engineering mud through the perfect cooperation between power mixer, excavator, control center and material storage equipment, so as to form a composite and stable base.

Introduction of soil stabilization system for soft soil

Soil stabilization system we also call it as soft soil in situ solidification and remediation system is a new construction scheme that uses soil solidifying agent to directly act on soft soil (such as sludge, sludge, beach, swamp, etc.) to solidify soft soil in situ to form a composite stable base.

The system is composed of storage bins, an control center and one or two power mixers. Combined with large and medium-sized excavators, the soil solidifying agent is directly transported to the soft soil which need to be solidified, evenly mixed and stirred to form a semi-rigid stabilized soil material.

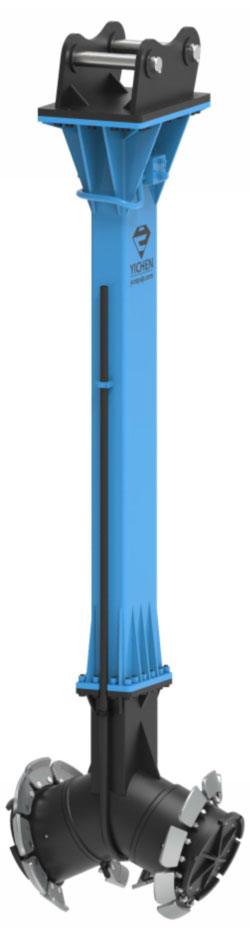

Power Mixer

Yichen® Soil Stabilization System Equipment Product Feature

Reduce the amount of commonly used materials such as gravel and crushed stone, thereby reducing project costs and saving resources and energy.

Solve the problems of soft soil mining, transportation and stacking, avoid secondary pollution, and contribute to environmental protection.

The system adopts computer fully automatic control, automatic deployment and delivery of soil stabilizer, one-button start and stop, simple operation.

The stabilization period is short, and a stable base can be formed 3-5 hours after mixing, which is convenient for later construction.

The stabilization effect is excellent, and the new stable base layer formed after stabilization has a certain bearing capacity without the risk of subsidence.

GPS positioning throughout the construction process, accurately locate the location of the excavator, and monitor the progress of the project.

Adopt green environment-friendly soil stabilizer to improve the ecological environment and reduce the harm of polluted soil to human health.

Yichen® Soil Stabilization System Equipment Advantages

The soil stabilization system developed by Yichen Environmental has created a new concept, overturned the requirements of traditional equipment for the jobsite, realized in-situ treatment, reduced the difficulty of engineering construction, and improved the treatment efficiency and effect. The composite stabilized soil formed after in-situ solidification of soft soil can obtain local materials and turn waste into treasure, which has many advantages:

1) After in-situ solidification of soft soil, the amount of commonly used inorganic binding materials such as sand and gravel can be reduced, so as to reduce the project cost and save resources and energy.

2) In situ solidification can solve the problems of soft soil excavating, transportation and stacking, avoid secondary pollution and help the effort of environmental protection.

3) The system adopts computer full-automatic control, conveying the solidifying agent according to the preset proportion, one key start and stop, and the operation is simple.

4) The solidification period is short. After mixing the solidifying agent and soft soil for 3-5 hours, the soft soil can form a stable base, which is convenient for later construction.

5) The solidification effect is excellent. The new stable base formed after solidification has a certain bearing capacity, which can ensure that heavy machines enter the site for construction without trapping risk.

6) By changing the composition, ratio and amount of solidifying agent, solidification and remediation can be carried out at the same time, reducing the treatment process.

7) The system is equipped with GPS positioning system, which can accurately locate the position of the excavator and monitor the construction progress in a large-area operation scene.

8) Adopt green environmental protection remediation agent to solve the problem of soil pollution, improve the ecological environment and reduce the harm of polluted soil to human health.

Yichen® Soil Stabilization System Equipment Application Case

Solidification Application

1. Roadbed construction

When the roadbed appears settlement and deformation. Repair by excavating its surface and hardening the soft soil about 1m deep.

2. Jobsite hardening

Hardening treatment of parking lot, stockyard, drilling well site, production and processing plant, etc.

3. Anti-subsidence and solidification of pipe trench and ditch

When the pipeline passes through the sludge ground during construction, there is no need to excavate and transport the sludge outside. solidified the sludge first and then excavation and backfill it.

4. Marshland solidification

The marshland is solidified for building large factories. There is no need to excavate , transport and stake the sludge elsewhere, then backfill with other materials. Just solidify and utilize the sludge on site by our soil stabilization system.

5. River bed solidification

Optimize river condition and environment by solidifying and leveling the river bed.

6. Solidification of Bridge and Tunnel

The foundation soil shall be solidified before the bridge is built. After the tunnel soft mud is solidified, it is excavated and then used as filling material.

7. Landfill solidification

The long-term accumulation of sludge, oil, plastics and other corrosive substances in the landfill can be used to build parks after solidification and burial.

Remediation Application

1. Remediation and improvement of heavy metal contaminated soil Stabilization and remediation of heavy metals in soil, engineering treatment of polluted soil and vegetation restoration, so as to reduce the potential danger of heavy metals in polluted soil to ecological environment and human health.

2. Contaminated soil remediation and acid-base neutralization

The content of heavy metals in the soil exceeds the standard and is alkaline. Acid and alkali neutralization is carried out through our

Yichen® soil stabilization system equipment.

Yichen® Soil Stabilization System Equipment Introduction to typical cases

Lianyungang Xuwei District dry bulk cargo transportation trestle beach solidification phase I Project

Construction volume: 800000 cubic meters

Construction equipment: 10 sets of

Yichen® soil stabilization system equipment (20 power mixers)

Length of power mixer: 4m, 5m and 6m (3m extension rod is customized, and the maximum solidifying depth reaches 9m)

Project Overview: the solidification project is a part of the construction of Lianyungang port. The construction site is a beach area with thick soil layer and soft soil. After completion, it is used for the stacking and transportation of large containers. Therefore, it has very high requirements for the stability of the foundation.

One week after solidification of Lianyungang port

Two week after solidification of Lianyungang port

Hangzhou Bay Expressway beach soft soil in-situ solidification phase I Project

Construction volume: 400000 cubic meters

Construction equipment: 9 sets of Yichen® soil stabilization system equipment (18 power mixers)

Power mixer length: 4m

Project Overview: the construction area of Hangzhou Bay expressway is located in the beach. The soil is soft, which can not ensure the mobilization of heavy equipment such as excavators. It is necessary to solidify the surrounding beach to ensure the subsequent highway construction.

Hangzhou Bay before solidification

Hangzhou Bay after solidification

Foundation solidification project of Shaoxing glass factory

Construction volume: 200000 cubic meters

Construction equipment: 5 sets of Yichen® soil stabilization system equipment (10 power mixers)

power mixer length: 6m (customized 2m extension rod, maximum solidifying depth up to 8m)

Project Overview: Shaoxing glass factory is located in the beach area beside the Qiantang River, which is very close to the river embankment and has high soil moisture content. It is impossible to build plants on this foundation. In order to ensure the construction safety, the foundation needs to be solidified first to make it a stable foundation with certain bearing capacity that meets the construction requirements.

Shaoxing glass factory before solidification

Shaoxing glass factory after solidification

Yichen® Soil Stabilization System Equipment Product Qualification

The Yichen® Soil Stabilization System Equipment is in compliance of CE certificatio

Yichen® Soil Stabilization System Equipment Deliver,Shipping And Serving

Wood case packed shipping. We provide equipment Installation guide and user training. We also provide spare parts and product customization services.

Yichen® Soil Stabilization System Equipment FAQ

1.Are you a trading company or a manufacturer?

We are the manufacturer.Visit Our Company Online

2.Can you can design the Horizontal Power Mixer of Soil Stabilization System according to our need?

Yes, we can customize the details of our equipment to meet your practical need.

3.How many excavators does a Soil Stabilization System need to work?

A Soil Stabilization System can meet the need of power mixers up to 2. Therefore, a Soil Stabilization System can supply the working needs of up to 2 excavators.

4.Can you send your staff to install the Power Mixer of Soil Stabilization System for us?

Yes, for the soil stabilization system, we will send our staff and offer installation worldwide.

5.Dose your company provide the soil stabilizer?

The soil stabilizer shall be configured according to the actual situation of the construction site. Customers need to conduct soft soil sampling and solidification experiments in the early stage to determine the proportion and dosage proportion of stabilizer. Our company can provide all-round consulting services. Customers can the raw material of the soil stabilizer locally to save cost.

6.Is it environmentally friendly to use your soil stabilization system for construction?

Of course, our soil stabilizer is liquid after being treated by the control center, and the power mixer will not raise any dust during operation. You can learn how our equipment works and what effect it can achieve through our soil stabilization system construction case video.

7.How do I know my construction period and how much soil stabilizer I need to consume?

This depends on the soil quality of the construction site, construction conditions, number of equipment and other factors. We will provide professional consulting services.

8.Does the control center need to be manned when the soil stabilization system is working?

No, once the control parameters are set, the control center can operate fully automatically.

9.What is your MOQ of the Soil Stabilization System Equipment?

The MOQ is 1 unit.

10.How long is your delivery time?

If we have available product in our stock. So we can ship product once the customer ordered. If the purchased quantity exceeds the inventory, we will determine the delivery time according to the product type, production quantity, customization situation as well as the delivery address.